Breathe Easy: Face Fit Testing

November 2018

The importance of protecting workers against inhaling hazardous dust and fumes is not a new topic of debate. 2018 will see the introduction of the new ISO 16975-3:2017 – a new standard specifically designed to provide guidance on how to conduct fit testing of tight-fitting respiratory protective devices.

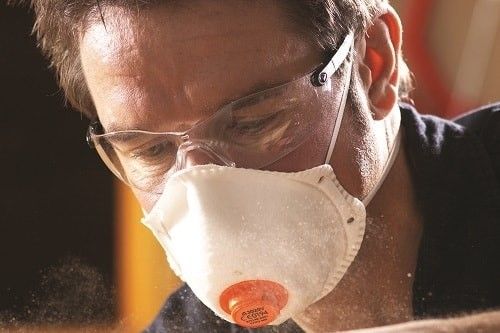

Not all faces are the same and neither are disposable respirators.

Fast-forward to the present day and the issue remains a hot topic of debate and a fundamental plank of international safety legislation.

So much so, a new standard specifically designed to provide guidance on how to conduct fit testing of tight-fitting Respiratory Protective Devices (RPD) (ISO 16975-3:2017) is to be implemented.

Protecting workers against the threat of breathing in dust and airborne particles is essential to remove the risk of them contracting respiratory-related illness and disease, such as lung cancer, silicosis, occupational asthma and chronic obstructive pulmonary disease (COPD).

Prevention is critical when it comes to

respiratory protection and respiratory protective equipment (RPE) is key to

safeguarding workers. In many cases, workers without proper protection and

exposed to dust and silicas will not necessarily show the signs of damage or

disease until

years later.

Higher-risk environments

By the nature of the material used, some sectors have a higher prevalence of dust and respiratory hazards including:

Construction, building and demolition—through concrete, stone, brick and mortar

Quarrying, mining and slate processing

Potteries, ceramics, brick and tile manufacturing

Foundries

Refractory production and cutting

Concrete product manufacture

Engineering

Architectural masonry manufacture

Kitchen cabinet and worktop manufacture

Grit and abrasive blasting, particularly on sandstone

Food

Carpentry

Recycling

For workers that are exposed to dusts, mists and fumes, the ideal scenario is to eradicate any possible contact between the worker and the dust hazard. Where they cannot be eradicated, workers need the right level of respiratory protection. The most common form of protection is a disposable respirator.

Selecting the

right dust mask

All dust masks and respirators provided for work environments must be approved to the appropriate standard and marked with the latest EN standard, which for disposable respirators is EN 149: 2001 +A1 2009.

FFP1, FFP2 and FFP3 signify different classes of respirator, offering varying levels of protection to the wearer (assuming they fit properly and are used correctly). FFP stands for filtering face piece. The higher the number the greater the protection so an FFP3 respirator should be used for all of the higher risk environments listed above.

Such respirators are designed to filter out particulates such as dust, mists and fumes. Even if you have this information, finding a suitable respirator is not simply a matter of choosing a model you like the look of or buying the cheapest.

Wider

considerations include:

Identify type and level of exposure

Evaluating airborne hazards in the workplace (or workshop)

Choose a disposable respirator based on FFP rating

Choose a comfortable and convenient model

When in doubt go with a higher level of protection.

Not all faces are the same and neither are disposable respirators. You might need to try different makes or sizes to find one that fits without leaking around the seal and letting dust in.

The only way you can know if the seal is good enough is by having a proper face fit test. Currently this is also the only way of meeting legal requirements.

Face-fit

testing

When it is launched, the arrival of the new ISO 16975-3:2017 standard will be another welcome addition to the ongoing challenge of helping protect workers through effective fit testing.

Designed to evaluate the effectiveness of the seal between the wearer’s face and the respiratory interface specific requirements for conducting RPE Fit Testing outlined in the new standard include:

Qualifications/competences of fit test operators

Specific fit testing procedures

Interpretation of fit test results

Record keeping.

Driving the

message

The reality is that many people across industry are still not aware of it or its full implications. Even more importantly we need to emphasise the message that effective fit testing is not simply a matter of providing RPE that ticks the performance box, but vitally is about the specific individual using it and the effectiveness of the fit it delivers.

For more information regarding Face Fit Testing and our in-house courses, please contact a member of the Sales Team on 01204 677811 or Click Here to download our full Course Schedule.